SUSTAINABLE IMPACT

From our products to how we show up for our customers, how we engage with our communities and how we tell our story, we’re always looking for new ways to innovate. It’s in our DNA.

In prior years, International would publish a comprehensive Sustainability Report that would statically sit on our website. After 30 years of sustainability reporting, we knew it was time to switch it up.

Welcome to our new Sustainable Impact page, where we’ll share more about the impact of our operations and products, our advancements to reduce environmental impacts, and how we address the needs of our customers, communities and workforce. This page will be updated regularly, so be sure to check back often.

In the spirit of transparency and to align with our core values, we track environmental metrics across a wide spectrum of areas. From our energy usage to reductions in water, waste, and emissions – we believe in keeping our stakeholders informed and measuring our progress for continuous improvement. Accordingly, these metrics are also consolidated with our sister brands in the TRATON Sustainability Annual Report. A breakdown of International’s 2024 environmental performance is shown in the following table.

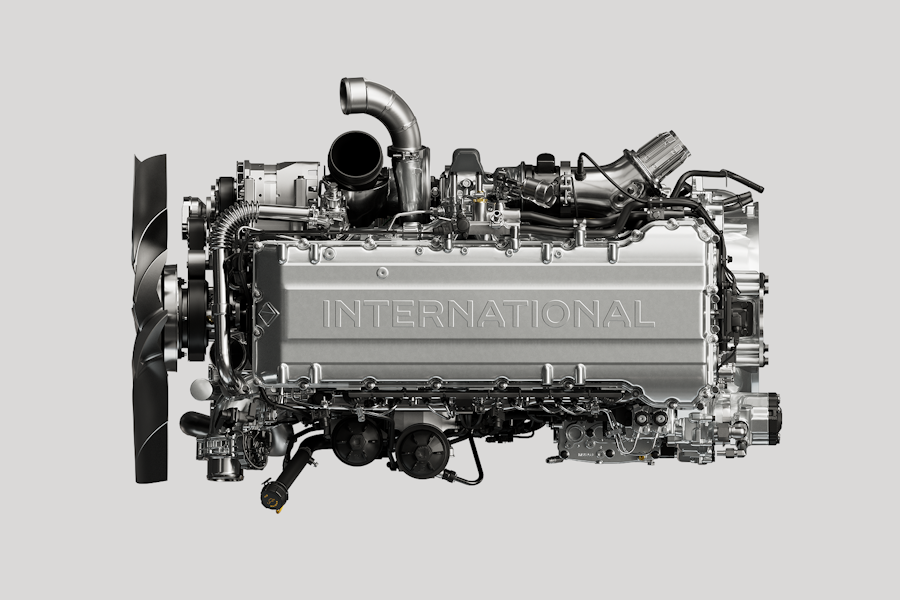

Speer Concrete's selection of the advanced International® HX® Series with S13® Integrated Powertrain and T14® Transmission began with a recommendation from Grooms Equipment. The family-owned ready-mix supplier now enjoys significant fuel savings with trucks reaching an unprecedented 7.2 miles per gallon, smoother operation for drivers, and reduced maintenance concerns, with plans to transition their entire fleet.

LEADING BY AT LEAST 5%

IN FUEL ECONOMY

S13 INTEGRATED

THERE ISN'T A ONE-SIZE-FITS-ALL SOLUTION. WE OFFER INCREMENTAL OPTIONS TO HELP OUR CUSTOMERS ACHIEVE THEIR INDIVIDUAL OBJECTIVES.

U.S. Air Conditioning Distributors move into battery electric vehicles (BEVs) began with a pilot of two International® eMV™ Series electric vehicles. They now operate four eMVs, with plans to reach seven by year-end. Drivers rave about the trucks' power, quietness, and range of 190-210 miles per charge, while the company enjoys significant fuel and total cost of ownership savings.

FLEET ELECTRIFICATION

ENERGIZING THE INDUSTRY

The growth in battery electric vehicles (BEV) is revolutionizing how the world does business. But it’s also raising new questions. To help lead the way, we’ve assembled an experienced, passionate and committed team to guide your transition to electric. From infrastructure planning to financing and training, our scalable, end-to-end solutions can be customized to your specific needs.

ELECTRIC AIRPORT

CATERING TRUCK

NORTH AMERICAN FIRST

When presented with a challenge, we find a solution. Working closely with Delta Airlines and airport ground support upfitter Mallaghan, we led the development of North America’s first electric airport catering truck. Designed to meet rigorous operational and environmental needs, the truck features advanced refrigeration and a scissor lift capable of reaching aircraft doors. This project is a shining example of how we put our values into action.

ON THE ROAD

LEADING THE WAY

In the heart of central Tennessee, a transformation is taking place. At the center of this change is a partnership between Putnam County Schools and International’s battery-electric-vehicle technology. For Putnam County, the decision to go electric was about leading the way. And with the help of a dedicated dealer and a forward-thinking transportation team, the district is proving that rural communities can be pioneers in clean, efficient and student-centered transportation. Since onboarding the IC Bus Electric CE Series, the school district has seen operational cost savings and a 65% reduction in energy costs.

SUPPORTING COMMUNITIES

With a vision to expand educational access and impact, our strategic grantmaking approach is designed to foster long-term, meaningful change in the communities where we live and work. As part of this commitment, International invites nonprofit organizations within our geographic footprint to apply for funding for up to three years. Through our Education Impact Fund, we invest in nonprofit partners who are transforming education and expanding opportunity — so that every student, regardless of background, can thrive.

CIRCULAR BUSINESS

International regularly sells and distributes approximately 3,000 remanufactured parts annually. Four central facilities collect and refurbish parts to support circularity — and our goal is to generate 20% of parts revenue from remanufactured parts.

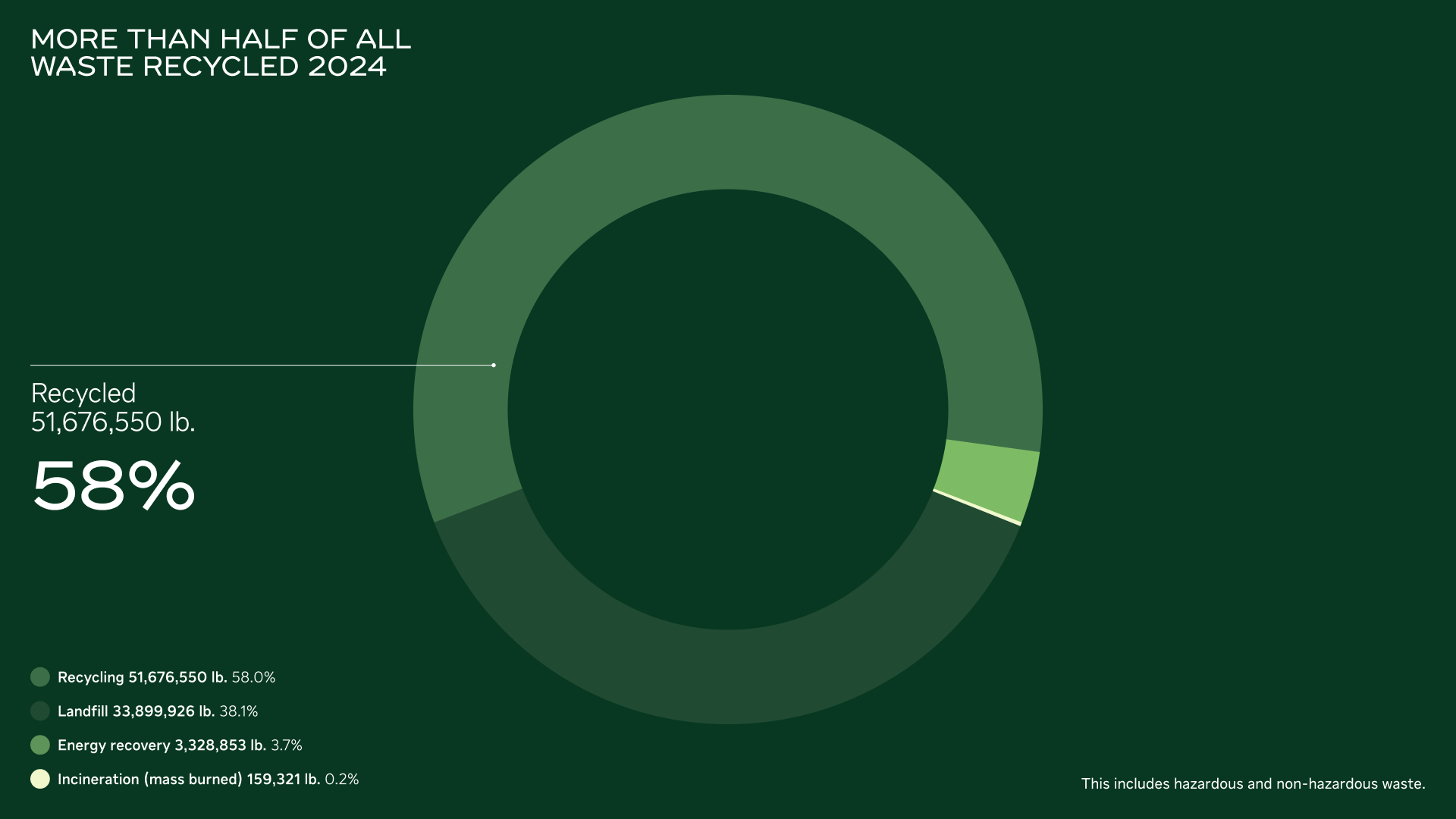

Even with increased production, International's 2024 waste management strategy successfully reduced overall waste generation by 6% from 2023. More than 50% of this waste was recycled and 38% was sent to landfill.

The company's investment in recycling equipment and partnerships with recycling firms have been instrumental in reaching this milestone. These collaborations have enabled International to recycle a variety of materials, including metals, plastics, paper, and electronic waste, thereby reducing its environmental impact and conserving natural resources.

In addition, International reduced the amount of hazardous waste generated from its operations by nearly 7%.

In 2024, our Escobedo Assembly Plant (EAP) produced 117.3 kg. of rich humus soil generated by composting cafeteria food waste with the help of 86 kg. of worms. As a result, this soil has fertilized 150 trees — reducing waste and improving the environment.

EAP also has 18 sheep that consume nearly 250 kg. of forage daily. The sheep produce 740 kg. of natural fertilizer, of which 65% is used to support tree growth.

The facility also hosts workshops to show and train employees how to compost at work and at home.

The Tulsa Bus Plant continues to improve our waste reduction and recycling targets through various waste management practices.

- Comprehensive waste segregation: This ensures materials are sorted at the source for efficient recycling and disposal, resulting in a landfill waste diversion rate of 64%.

- Employee engagement: Regular training sessions and awareness programs educate employees about the importance of waste reduction and recycling, encouraging them to adopt sustainable practices at work and at home. This engagement led to better management of dumpsters and wood waste.

- Advanced recycling technologies: Recycling technologies have enhanced the efficiency and effectiveness of the facility's recycling processes, enabling the recovery of valuable materials from waste streams. Tulsa acquired an auger to breakdown, compact, and maximize dumpster fill.

The San Antonio, Texas, (STX) Manufacturing Plant’s permanent wastewater pre-treatment system became fully operational in December 2024, marking a major upgrade from the previous temporary setup. Unlike the old system, the new one includes equalization tanks and automated recirculation, allowing non-compliant wastewater to be reprocessed until it meets discharge limits.

Designed to remove heavy metals and balance pH levels — especially from e-coat rinsing — the system now supports real-time monitoring for zinc, nickel and pH. If any readings fall outside of range, pneumatic valves kick in to automatically redirect flow for re-treatment, ensuring compliance before discharge.

From planting trees in Mexico to cleaning Chicago beaches and neighborhoods, International helps employees better care for our communities — and the planet.

RESPONSIBLE PROCUREMENT

At the beginning of 2024, International launched a supplier sustainability rating (S-Rating) which is a factor in the company’s sourcing decisions and business awards to new and current suppliers. To achieve a positive S-Rating, suppliers and business partners must meet or exceed criteria around workplace safety, working conditions, environmental management, and energy usage. Suppliers are also scored on how well they manage high-risk raw materials, like batteries for our electric trucks and buses, and how responsibly they handle business with their own supply base.

Working with suppliers who have positive S-Ratings means we are putting our money where our mouth is and staying aligned with our core values, particularly when it comes to responsibility. It provides confidence that the suppliers we work with respect the environment, human rights, and working conditions within our company's Code of Conduct.

As of January 2025, suppliers must have a positive S-Rating to be eligible for most new business awards above $250,000 per year. More than 80% of our core suppliers — those providing materials and components used in our vehicles and daily operations — have a positive S-Rating.

SUPPLIER DIVERSITY

We are only as strong as our suppliers. In 1981, we launched a supplier diversity program. Today, we continue to invest in partnerships with minority, women, veteran, small, and disadvantaged businesses.

QUALITY

Quality is our core. We work side by side with our suppliers to make sure every part, product, and service meets the highest standards for safety, reliability, and performance. Our approach is practical and grounded — we focus on what works, and we’re always looking for ways to do better.

HUMAN RIGHTS DUE DILIGENCE

Respecting human rights is an imperative, both internally and with our partners. We have in place a cross-functional Business & Human Rights Committee to keep us accountable and proactive. We updated our Code of Conduct for Suppliers & Business Partners to make our expectations clear, and we rolled out mandatory human rights training for all employees and contractors. We also introduced new tools to spot and address risks in our supply chain, so we can act quickly and do what’s right.

RUN WITH US

Curious about the next big launch? Recent innovations? Subscribe to our newsletter and get the latest news on our products and services direct to your inbox.

Subscribe